Fort Wayne Doc First in Indiana to Implant 3D Printed Knees

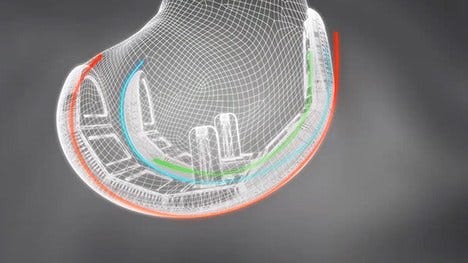

An automated design process uses proprietary algorithms to map the surface of the joint in three dimensions.

An automated design process uses proprietary algorithms to map the surface of the joint in three dimensions.

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowA 70 year-old patient in northern Indiana living with two replacement knees was puzzled at her most recent follow-up appointment. Her second knee was replaced just weeks ago, and the first about two years ago—but she asked her surgeon why recovery the second time around was pain free, unlike her first knee replacement. The answer, says Dr. William Berghoff, is cutting-edge technology that’s taking the orthopedic sector by storm. The first surgery for Berghoff’s patient used an “off-the-shelf” replacement knee, but her second knee was custom made using 3D printing technology to be an exact replica of her unique anatomy.

“It’s crazy stuff,” says Berghoff, baffled himself by the technology. “It’s taken us into that sort of space age technology. This is the leading edge of something that’s going to be the mainstay. If we have this conversation in five years, everyone will be getting this type of knee.”

Berghoff, a joint reconstructive surgeon at Ortho NorthEast in Fort Wayne, is the first doctor in Indiana using ConforMIS Customized Knee Implants. The product was developed by Massachusetts-based medical device company ConforMIS, which was founded in 2004.

The process starts with a CT scan through the patient’s hip, knee and ankle. Software developed by ConforMIS then converts the two-dimensional CT data into a 3D wax model of the knee before disease—such as osteoarthritis—set in. Using 3D printing technology, the implant is built from the ground up to be an exact fit with the patient’s unique anatomical bone geometry—basically, customizing the size and shape of the joint. The method is in stark contrast to how knee implants are traditionally done with devices that are mass-produced.

“The reason I jumped on board is because after 22 years of doing knees, you see the downside of off-the-shelf technology; it doesn’t quite fit the patient right, you have to make some comprises—gives and takes—during surgery,” says Berghoff. “This knee addresses that.”

Using traditional implants, a patient’s knee is typically cut to achieve the appropriate fit with the implant.

“Because [ConforMIS] is a custom knee, we remove about one-third less bone to put the implant in,” says Berghoff. “We’re saving bone; we’re not making as many deep cuts into the bone, and I think that has a lot to do with the decreased pain afterwards.”

The ConforMIS knee is also custom designed to fit the patient’s unique alignment throughout the entire leg—hip, knee and ankle—which Berghoff says is the second critical factor for knee implants. He notes some people are more bow-legged or straight-legged.

Berghoff has been using the ConforMIS knee for about six months, totaling about 70 procedures. While he’s the first surgeon in Indiana to adopt the technology, he says “it’s going crazy” in regions of the U.S. that are known for people living active lifestyles. It’s unclear if any companies in Indiana’s orthopedic cluster in Warsaw are working on similar technologies; e-mail messages sent to the major manufacturers were unanswered at publication time.

Despite the improved technology, he notes the ConforMIS implant doesn’t cost much more than the typical knee replacement.

“The premium on it compared to other knees is a little bit more expense, but the justification is that you’re going to have a knee for 20 years that’s going to fit you and be a better knee for you,” says Berghoff. “I’ve yet to have one insurance company push back and say, ‘We’re not going to cover this,’ which is beautiful, because I think they recognize the technology.”

While Berghoff says the technology is being developed for other joints, he says the greatest need existed in knee replacements.

“Knees are so much more intricate in terms of ligaments, balancing and alignment,” says Berghoff. “This is where the technology needed to be first and where it shines. The hip’s more of a ball and socket joint; it doesn’t have ligaments and doesn’t have to be balanced like the knee.”

Berghoff says some surgeons are even implanting the devices as an outpatient procedure, eliminating the typical three to five day hospital stay.

“I’m excited about having my patients use this, and I’m more excited about having everyone start using technology like this around the country,” says Berghoff. “I think everyone’s going to get there eventually. Once you see this in action, it’s like, ‘Wow, this is the future.’”