Partnership Puts IU Closer to 3D Printing Transplantable Organs

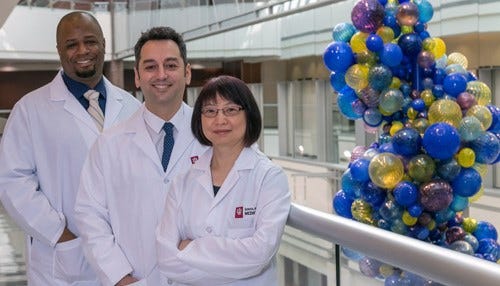

The IU team of researchers includes: Lester Smith

The IU team of researchers includes: Lester Smith

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowThe shortage of transplantable organs is, simply put, insurmountable. About 20 people die each day in the U.S. waiting for organ transplants, according to the Organ Procurement and Transplantation Network. Even an available organ may not match a waiting patient due to size, blood type or tissue type. Rather than wait on organs, a team of scientists at the Indiana University School of Medicine (IUSM) wants to build them—personalized, 3D-printed organs on-demand—and a $9 million deal with the private industry is making it plausible.

IUSM Assistant Professor of Surgery Dr. Burcin Ekser leads the school’s xenotransplantation research lab; xenotransplantation is the transplantation of, in this case, organs from one species to another. The research centers on pigs, because their organs and physiology closely resemble humans’.

Ekser, who is also an IU transplant surgeon, says there are two key areas in xenotransplantation. The first is using organs from genetically-engineered pigs to potentially transplant into humans. Scientists are studying CRISPR pigs for this purpose; the swine are born with altered genomes to make them better potential organ donors for humans. While this method could be starting clinical trials in about one year, Ekser says the technique requires a five-month pig pregnancy, plus time for the piglets to grow large enough to supply human-size organs.

The IU lab is dreaming even bigger, focusing on the second key area of research in xenotransplantation: 3D printing organs with pig tissue, ultimately, for human transplantation. The IU researchers use genetically-engineered pig liver cells to 3D print pig liver models.

“We can [3D] print the miniature pig organ models within a day, grow and mature them within five days and then [do immunological modeling] to get the response we want, basically, in two weeks,” says Ekser. “It’s a very quick process and much cheaper than making the entire pig. The other positive consequence is we don’t sacrifice animals for research; we’re just using cells and creating our organ models in the lab.”

3D printing is a key strength of the IU lab; it’s one of only two academic labs in the country to have a cutting-edge Cyfuse Regenova 3D bioprinter. The technology prints “scaffold-free” biological tissue, meaning it’s free-standing tissue that doesn’t require a scaffold to support it.

The IU team, which includes Dr. Lester Smith and Dr. Ping Li, has another critical area of expertise: “perfusing,” which means pumping human blood through the pig organ model to mimic what would happen in the body, “so we can get the immunological response we want based on the gene combinations,” says Ekser.

The stature and accomplishments of the IU lab helped it recently earn a $9 million grant from Lung Biotechnology PBC, a Maryland-based organ transplantation technology company. Ekser says the funding and exchange of knowledge between IU and Lung Biotechnology will speed the two entities closer to their common goal: organs on-demand.

“So people go to the hospital in the future, and we will print the organ you need—it’s also called personalized medicine,” says Ekser. “Then we basically will not have any shortage of organs, and our hope—my aim as a transplant surgeon—is that no one will die while they’re waiting for a transplantable organ. The aim [of the collaboration] is to advance the field, so we can reach that goal as soon as possible.”

Now 3D printing and perfusing mice-size models, the IU lab will focus on gradually stepping up in size—building toward its mission of making life-saving organs.

Ekser says each success in research steadily moves the IU team forward.

Ekser says partnering with private companies is a critical strategy to advance academic research from the lab to the patient’s bedside.